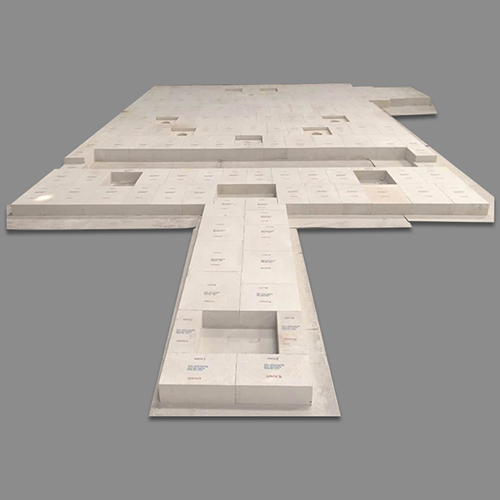

Feeder expendables are the last link between glass melting and glass forming and therefore should display high thermal shock resistance, low blistering rate and good corrosion resistance. We understand the criticality of these refractory and ensure glass contact properties, geometry and dimensional precision

SCL provides the complete range of Feeder Expendables for every kind of glass production including Container Glass, Tableware, Pharmaceutical glass, Cosmetics, Crystal glass etc. They are mainly manufactured by vibro-casting and hydraulic casting pressure processes.

Our Feeder Expendable range includes:

A. Standard Spout System

- Standard expendables in SCL-33 and SCL-15.

- Zirconia-free Expendables in SCL-11, SCL-44 and SCL-45

- Long life Expendables in SCL-21 and SCL-35

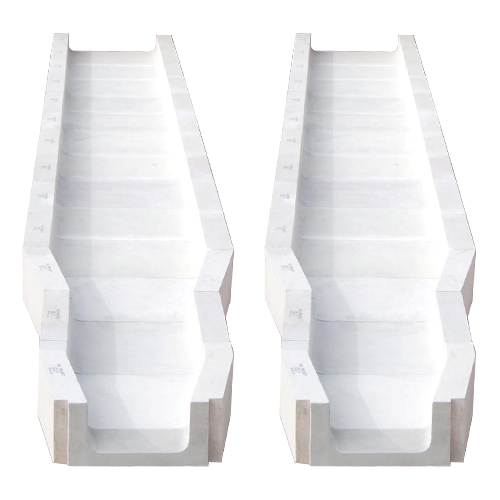

B. Metering Spout System

Our Metering Spout system range includes:

- A special metering tube with a taper on the bottom that leads into a matching taper on the spout throat to form a metering valve.

- A special shaped orifice ring that allows more space around the outer cavities.

- A special metering spout bowl with an elliptical outlet and tapered throat to match the special shaped orifice ring and tapered tube.

- A heat baffle located inside the tube.

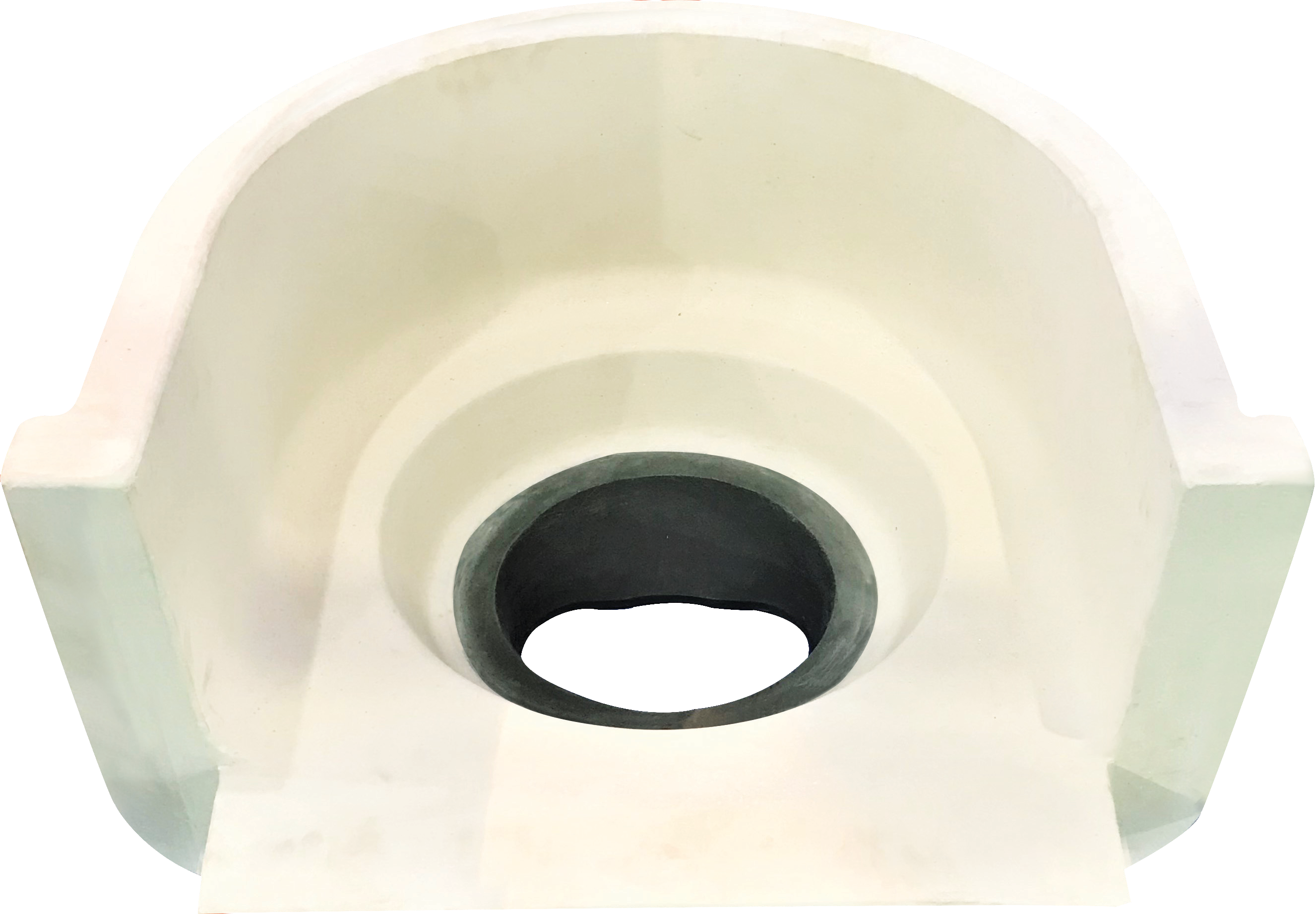

C. Inserted Orifice Rings and Spouts

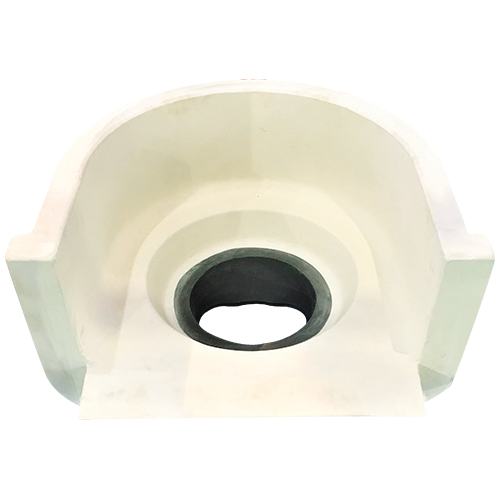

Orifice Rings

Due to corrosion from alkali present in the glass and also due to quantity and temperature of glass, the bores of the Orifice Rings get bigger and controlling gob weight becomes a frequent problem. This phenomenon becomes more prominent with higher speeds and smaller gob weights.This problem leads to frequent job changes of Orifice Rings.

In case of Type III glass, the life of an Orifice Ring (SCL-33 quality) is normally between 15-45 days depending on the bore size, quantity and temperature of glass. However, with more corrosive glasses like Type I Glass, Opal Glass, etc. the changing time of Orifice Ring can be down to 2-3 days severely affecting the productivity. Every change of Orifice Rings consumes about 1-2 hour of production time to reach the stable production level again.

SCL offers a long-term solution to this problem with Chrome Inserted Orifice Rings in SCL-33 CL & SCL-15 CL quality. These chrome inserted Orifice Rings are known to last for more than 180 days in Type III glass and more than 45 days in Type I glass. This greatly increases Orifice Ring change intervals and thus productivity. That also means improved quality of glass as low corrosion of refractory means cleaner glass.

Chrome Inserted Orifice Rings are designed to avoid any leakage from the joints. These Rings are manufactured in all types and sizes of Orifice Rings with very little modification from the existing designs.

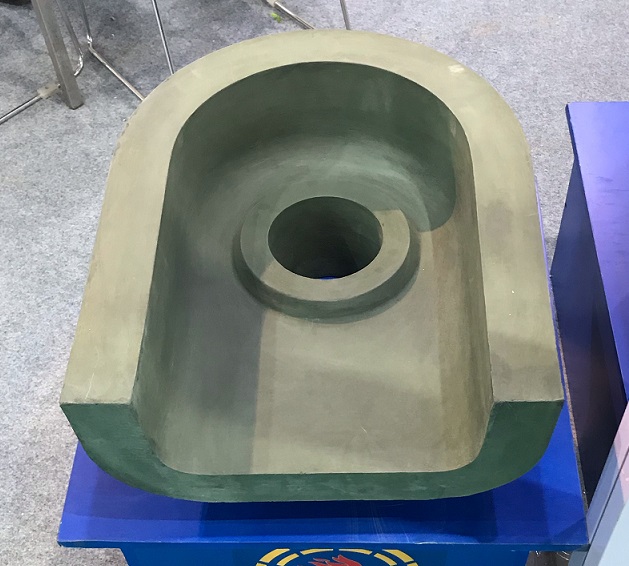

Spouts

SCL offers Chrome Inserted Spouts to achieve a much longer life as compared to standard SCL-15 quality. Each spout change takes about 12 hours of precious production time which can be saved by using these spouts. The Chrome Inserts are designed and pre-fitted at Spout throat to provide leakage proof joints. All type and design of Spouts can be fitted with these inserts and a life of more than two times can be achieved over the normal spouts.

D. Fused Silica Expendables

SCL manufactures full range of expendables in SCL-FS99E for application in Opal glass and Borosilicate glass.

E. Full Chrome Expendables

SCL manufactures full range of expendables in SCL-CR85 for application in Opal glass and Borosilicate glass.

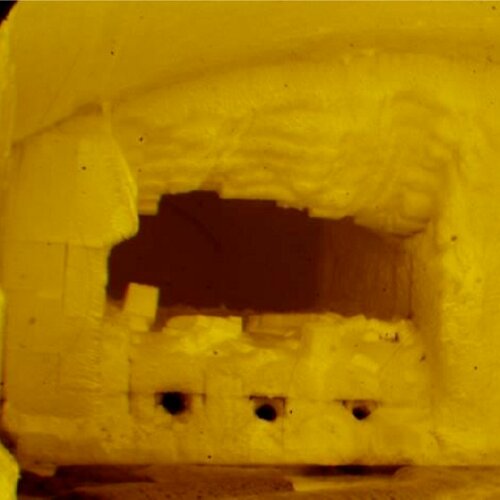

F. Stirrer System

SCL manufactures both paddle type and screw type stirrers for glass conditioning and coloring forehearths. Our high-zirconia next-gen brand SCL-22S provides excellent performance life for stirrers.

SCL Tubes and Plungers

SCL Chrome-Inserted Metering Spout

SCL Chrome-Inserted Orifice Rings

SCL Full Chrome Spout