Over 30 years of research and development in the glass market have enabled us to pioneer innovative glass solutions. Over all these years, we have gained the trust of over 200 satisfied customers in a wide spectrum ranging from the largest manufacturers to the customized specialty glass makers across the globe.

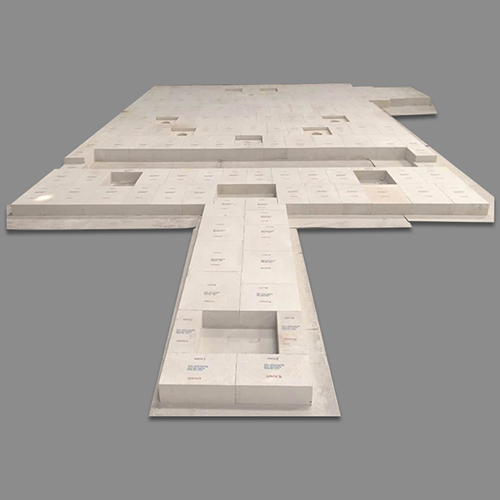

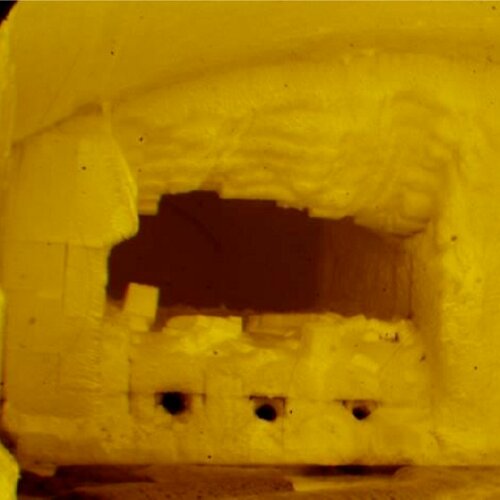

SCL caters to various furnace designs which include HORN, SORG, KTG and other designs offering distinctive advantage to the customer.

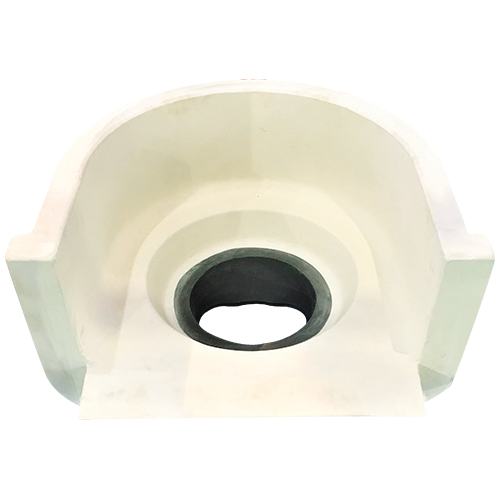

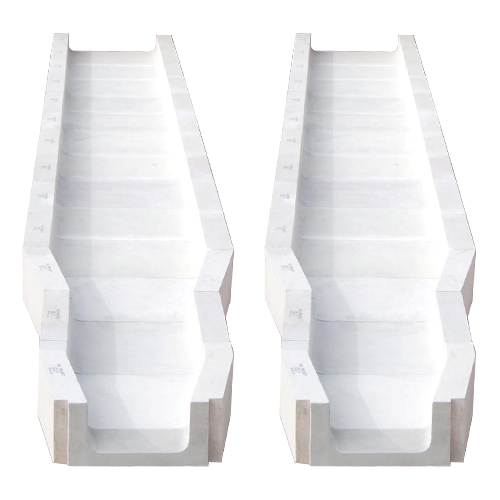

SCL range of refractories for the Glass industry can be classified in Five major areas: